Du-Lite SD Compound

$349.75

Du-Lite SD Petroleum Compound

Du-Lite SD Petroleum Compound removes occluded, trapped or retained salts from blind holes or barreled actions. Du-Lite SD will penetrate areas where salts are trapped, removing or neutralizing salts, therefore, solving this problem.

Du-Lite ships SD Compound in heavy duty industrial 5 Gallon and 55 Gallon Drums.

PLEASE SEE IMPORTANT SHIPPING INFO BELOW

CALL FOR PRICING ON 55 GALLON SIZE

- Description

- Additional information

- Reviews (0)

- Important Shipping Information

- Important Pricing Information

Description

Du-Lite SD Petroleum Compound

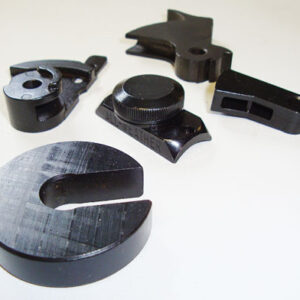

Du-Lite SD Petroleum Compound removes occluded, trapped or retained salts from blind holes or barreled actions. Some parts have a tendency to absorb or retain processing salts during the black oxide process. These trapped salts may not show up immediately on finished work, but, in time, the retained salts will appear in the form of a whitish powder or haze on the finished piece.

Barreled receivers, cast and malleable iron, powdered metal parts, laminated parts and parts with blind holes are particularly susceptible to this problem. Du-Lite’s SD Compound will penetrate areas where salts are trapped, removing or neutralizing salts therefore solving this problem.

Du-Lite ships SD Compound in heavy duty industrial 5 Gallon, 55 Gallon and 225 Gallon Drums.

Additional information

| Weight | N/A |

|---|---|

| Size | 225 Gallon, 5 Gallon, 55 Gallon |

Be the first to review “Du-Lite SD Compound” Cancel reply

You must be logged in to post a review.

For 55 Gallon Containers Please Call for Freight Pricing

For 225 Gallon Size, Please Call for Pricing.

Reviews

There are no reviews yet.